Success Stories

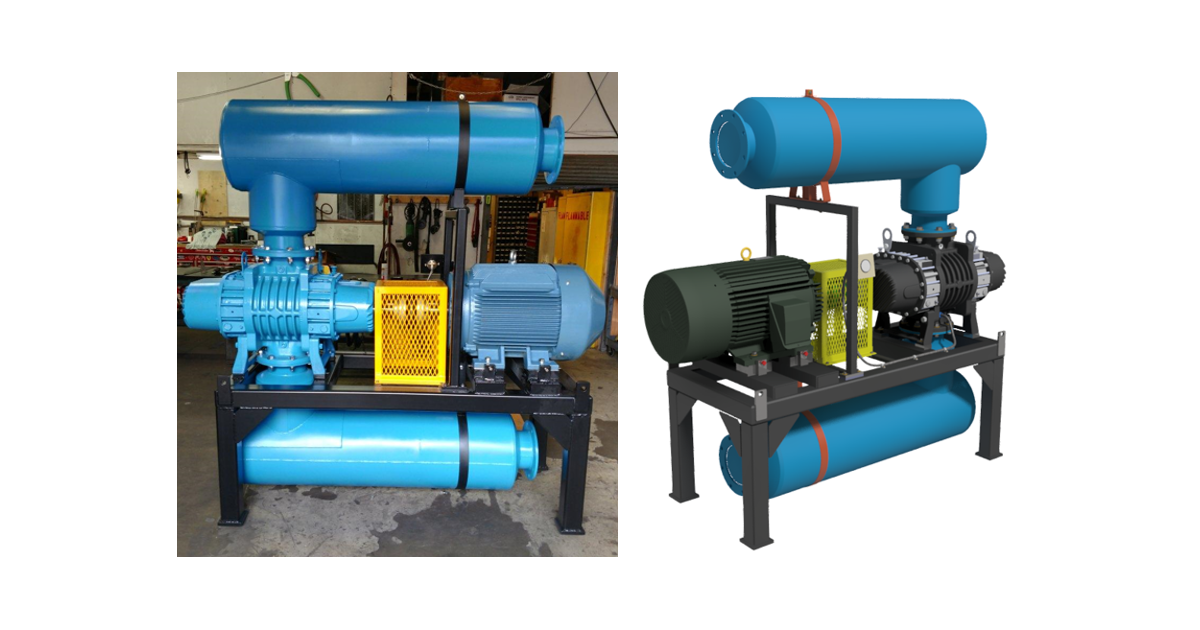

Custom engineered pressure blower package for pneumatic conveying in a cheese processing application

- M-D Pneumatics® 7013 PD Plus 2-lobe blower

- 100HP NEMA 60Hz-230/460V 3Ph TEFC electric motor

- Custom welded steel frame with jacking bolts for easy motor alignment

- Direct coupled with coupling guard

- Combination chamber-absorptive type inlet and discharge silencers for premium attenuation

- PRV to prevent a rise in internal pressure in excess of maximum pressure rating

- Split disk check valve to prevent backflow

- Discharge pressure gauge to monitor blower discharge pressure for performance evaluation

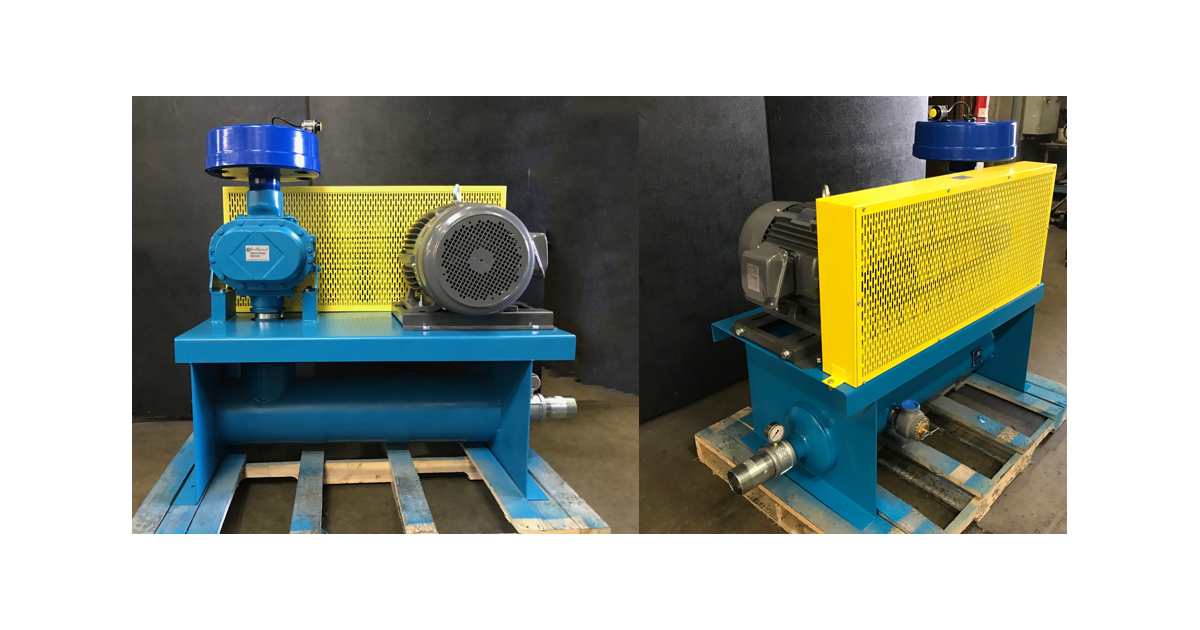

Custom pressure blower package for pneumatic conveying of Portland Cement

- M-D Pneumatics® 4504 Equalizer 2-lobe blower

- 25HP NEMA 60Hz-230/460V 3Ph TEFC electric motor

- Adjustable motor slide mounting base

- V-belt drive assembly with belt guard

- Air intake filter with pressure drop service indicator gauge to monitor filter performance

- Chamber-absorptive discharge silencer and base to reduce air borne noise

- PRV to prevent a rise in internal pressure in excess of maximum pressure rating

- Split disk check valve to prevent backflow

- Discharge pressure gauge to monitor blower discharge pressure for performance evaluation

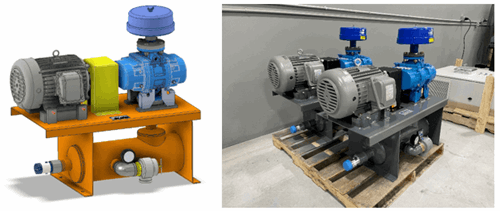

Custom pressure blower package to provide areation for steeping process to produce malt

- M-D Pneumatics® 3203 Qx 3-lobe rotary positive displacement blower

- 10HP NEMA 60 Hz-230/460V 3 phase TEFC frame electric motor

- Direct drive system with coupling assembly, coupling guard and motor jacking bolts for alignment

- Inlet air filter/silencer

- Integral welded base frame and chamber-absorptive discharge silencer to reduce air borne noise

- Pressure relief valve to prevent a rise in internal pressure in excess of maximum pressure rating

- Split disk check valve to prevent backflow

- Liquid filled discharge pressure gauge to monitor blower discharge pressure for performance evaluation

Custom pressure blower package for recirculating nitrogen gas for process cooling application

- M-D Pneumatics® 5518 PD Plus 2-lobe rotary positive displacement blower with mechanical seals

- 30HP NEMA 60 Hz-230/460V 3 phase TEFC frame electric motor

- Direct drive system with coupling assembly and coupling guard

- Custom welded steel base frame with motor jacking bolts for alignment

- Pathfinder Systems Inc. premium chamber/absorption DB series inlet and discharge silencers

- Blower monitoring safety devices such as PRV, temperature sensor, pressure gauge, etc. provided by the end customer

- Designed for 24/7 duty cycle