PD Blower Material and Accessory Options

Rotary positive displacement blowers, a.k.a. PD blowers, are manufactured and assembled with standard factory materials and seals. MD-Kinney’s MD-Pneumatics® legacy brand PD blowers are available with upgrade options to improve a PD blowers service life depending on the operating parameters and environment in which the PD blower will operate in. Here are some of the available upgrade options:

Special Materials

Cast iron is the standard material of construction for PD blower housings, endplates and ports and use ductile iron rotors. Ductile iron is an upgrade option for housings, end plates and ports with enhanced impact strength over cast iron. Cast steel provides enhanced strength and impact over both cast iron and ductile iron and is recommended for lower temperature applications. It is a preferred material in the petrochemical industry. Stainless steel is available for improved corrosion resistance but at an additional cost over cast iron. Bi-protect coating is a lower cost corrosion protection solution compared to stainless steel. It is a thin coating and can be damaged by process debris. Bi-protect is best with processes that are marginal with cast iron and need to extend service life however it is not always satisfactory for heavy duty acid and chemical applications. A no yellow metals option is also available where standard brass /bronze components are replaced with iron/steel/stainless steel materials.

Plugged Rotors

Typically, PD blowers are standard with hollow rotors. O-ring plugged rotors are available on the MD-Pneumatics® PD Plus series blowers with two-lobe rotors only and recommended for condensible process applications or those requiring liquid injection. The blower unit may become unbalanced if liquids should condense in the hollow rotors resulting in internal damage. This would require repair and/or replacement of the rotors or housing which is costly.

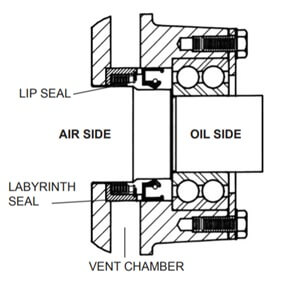

Vent to Drain

Vent to drain is recommended for any application where the unit is moving condensible gas streams. Drain valves are plumbed to the vent area which is an empty space between the process chamber and the oil sump. When the drain valve is opened it will allow process gas to escape. The drain valve could be a manual valve or replaced with a customer supplied electronic solenoid operated by a timer. The drain needs to be operated often enough to assure no liquids are accumulating in the vent.

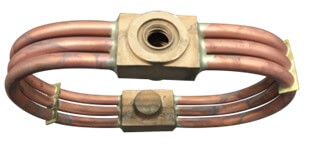

Cooling Coils

MD-Pneumatics® has for years offered cooling coils installed within the oil reservoirs to reduce oil temperature and improve oil viscosity thereby increasing oil life between oil change intervals. They are recommended for applications with discharge temperatures exceeding 250° F for periods of 4 hours or more per day. The oil target temperature should be between 150°F and 200°F. If cooling water is too cold or circulated when the blower is not in operation, then the possibility of condensation occurs resulting in water collecting in the oil reservoir, increasing the risk of premature bearing failures.

External or Integral Lubrication Systems

MD-Pneumatics offers external lubrication and integral lube oil temperature protection systems when the following situations exist:

• Operation of more than 4 hours per day

• Run cycles of more than 2 hours with less than 4 hours of shutdown between cycles

• Blower longevity is important to the end user

• Blower operation may be more strenuous on the blower than the blower application design point

• Blower discharge temperatures ranging between 250°F to 400°F

The advantages of an external or integral lubrication system are as follows:

• Filtration of the oil

• Cool oil delivered to bearings

• Larger oil reservoir

• Larger circulation rate on bearings

• Longer period between oil changes

SPM Mounting

Shock pulse monitors are commonly used to detect early stages of bearing failure. For MD-Pneumatics® blowers, endplates come factory-drilled with mounting locations for shock pulse monitors. This feature is required for oxygen and hydrogen service and highly recommended for other potentially flammable or explosive processes.

Please contact Northwest Flow Technologies to learn more about the optional MD-Pneumatics® PD blower material and accessory options.